📦 現貨到貨|刀劍用頂級砥石系列

#Meito認證砥石 #有本製砥所

🔧 產品資訊

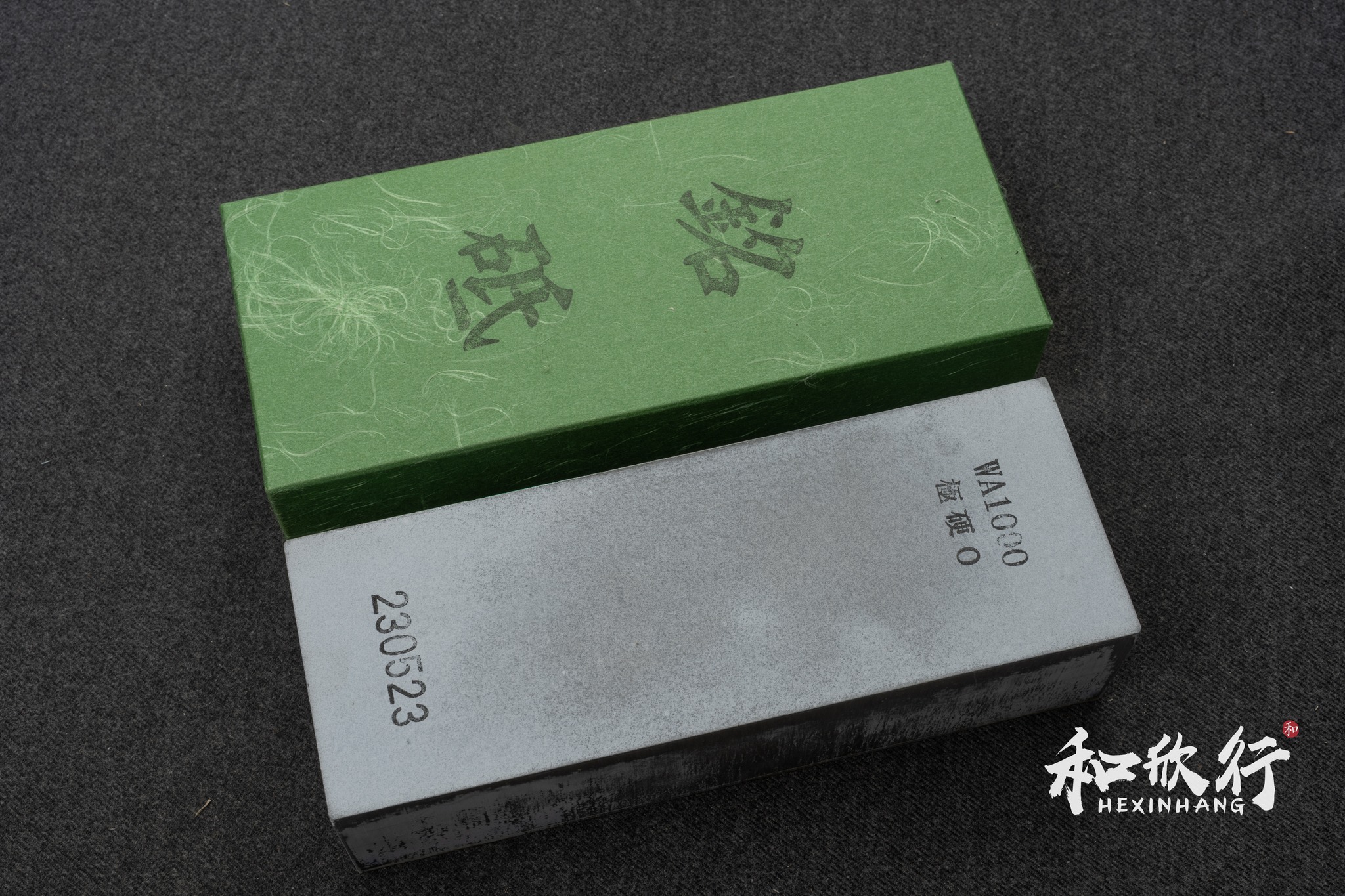

品牌:有本製砥所 Arimoto Seitosho

品名:刀劍用 銘砥 Meito 認證 人造 WA 極硬 #1000(改正砥)

產地:日本京都

尺寸:200 × 75 × 50 mm

重量:約 2155 g ±

售價:NT$ 6,500

Japanese Whetstone Meito(Authenticated)Kaisei WA #1000

WA1000(白剛玉 / White Alumina)

━━━━━━━━━━━━━━━━━━━

✨ 產品特點|極硬 × 高研磨力 × 中仕上げ最強過渡砥石

此款 Meito 認證 WA #1000 改正砥石屬於

「極硬、高密度 × 研磨力極佳」的中段砥石。

它在刀劍研磨流程中,是負責

刃部修整 → 進入細仕上げ 的重要核心砥石。

主要特性如下:

🔹 修整能力極強

對嚴重受損、缺口的刃部效果最佳,可迅速整地與矯正。

🔹 實際研磨細緻度 ≈ 他社 #3000

刃面細膩、光澤柔和,比一般 #1000 完成度更高。

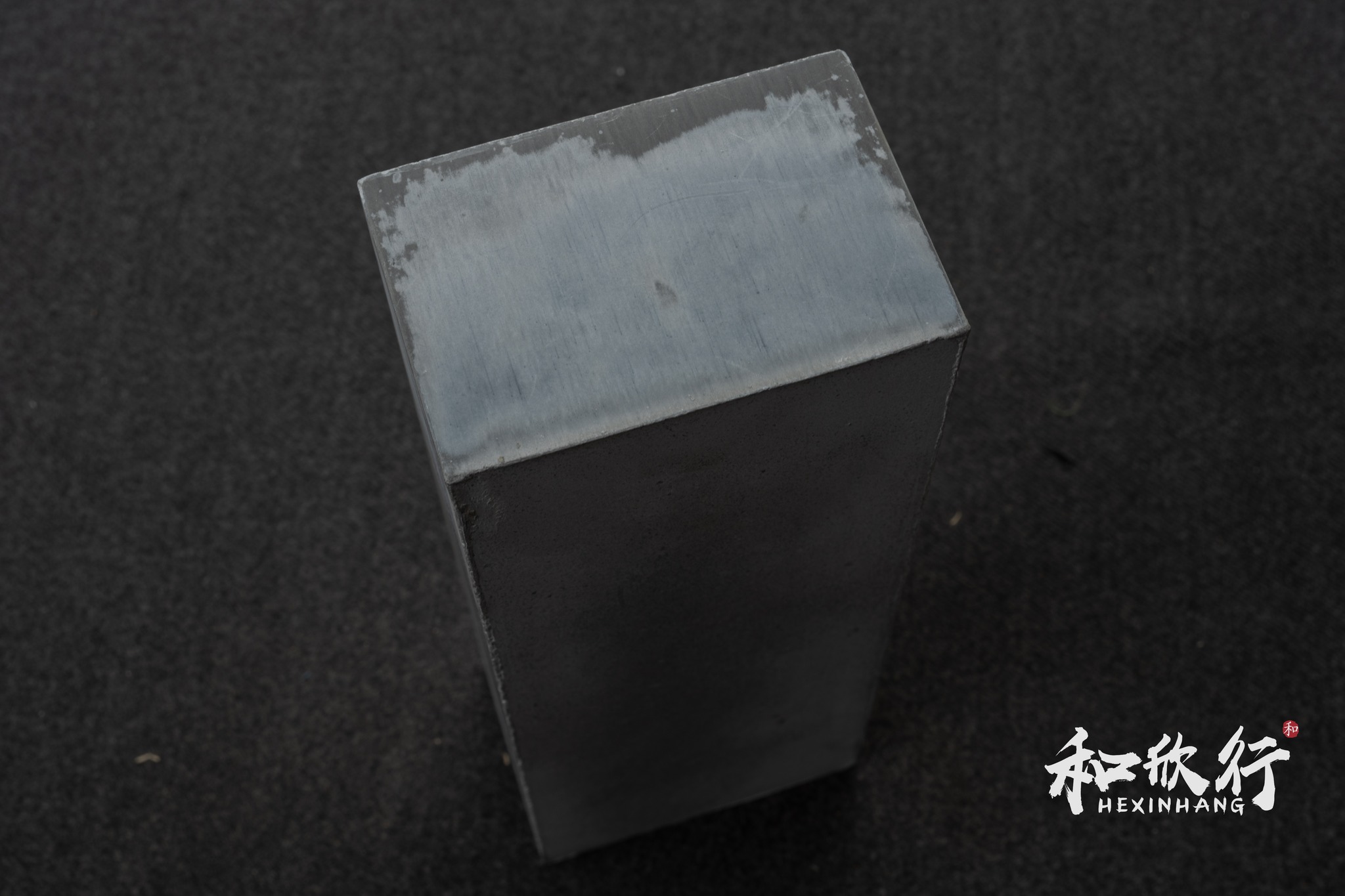

🔹 高密度不吃刀、不留深傷

研磨表面均一,能順利接上細番砥石。

🔹 刀劍&高級包丁的中段砥石首選

專業研師常用其進行形狀調整、地肌過渡。

━━━━━━━━━━━━━━━━━━━

⚔️ 刀劍研磨定位:中仕上げ前的核心砥石

刀劍研磨講求:

・刃紋線條

・刃口完整度

・地肌細緻度

・階段銜接品質

此款 WA #1000 的定位就是:

👉 從修整 → 進入細緻研磨 的最佳過渡階段。

※ 正式刀劍仕上げ仍需使用天然砥石,如:

・內曇(Uchigumori)

・鳴瀧(Narutaki)

本品即是「進入天然砥前的最關鍵人造砥」。

━━━━━━━━━━━━━━━━━━━

🧱 品牌介紹|有本製砥所 Arimoto Seitosho(京都)

京都的傳統砥石工房,

提供刀劍、包丁、工業用等多類用途砥石。

特色:

✔ 每塊砥石皆為職人手工製作

✔ 可小量客製、調整配方番號

✔ 與多位刀劍研磨師合作開發

✔ 被視為「能穩定替代部分天然砥」的頂級人造砥

在天然砥石取得困難、品質差異大的當下,

有本製砥所已成為 關西 / 西日本研師圈高度評價品牌。

━━━━━━━━━━━━━━━━━━━

🧩 開發理念|「刀劍研磨師理想中的人造砥石」

天然砥石的問題:

・個體差異大

・品質不易掌控

・尺寸取得困難

因此刀劍研磨師 真澄會・真津仁彰先生

與有本製砥所共同開發出此系列 Meito 認證人造砥石,

使刀劍研磨流程更穩定、更可控、更高效率。

━━━━━━━━━━━━━━━━━━━

⚙️ 使用建議

・灑水、噴水潤濕即可(❌ 禁止浸泡)

・使用後以清水沖淨、陰乾保存

・避免日曬、高溫、急速乾燥

・定期用修整砥 / 金剛砂板維持平整度

━━━━━━━━━━━━━━━━━━━

📌 適用對象

✔ 刀劍研磨師

✔ 專業包丁研師

✔ 需要高研磨力與穩定接刀的使用者

✔ 想要人造砥石中最接近天然砥體驗者

━━━━━━━━━━━━━━━━━━━

📩 歡迎私訊洽詢/可提供更多實拍圖

#有本製砥所 #ArimotoSeitosho #京都製

#Meito認證 #WA砥石 #改正砥 #刀劍用砥石

#仕上砥石前砥 #刀剣研磨 #包丁研ぎ

#研磨工具 #職人砥石 #HeXinHang #和欣行

📦 Ready Stock Arrival

#PremiumSwordPolishingStones

#MeitoCertifiedWhetstone

Brand: Arimoto Seitosho (有本製砥所)

Model: Meito Authenticated Synthetic WA Ultra-Hard #1000 (Kaisei Stone)

Origin: Kyoto, Japan

Size: 200 × 75 × 50 mm

Weight: Approx. 2155 g ±

Price: NT$ 6,500

Japanese Whetstone Meito (Authenticated) – Kaisei WA #1000

Abrasive: WA1000 (White Alumina / 白剛玉)

This Meito-certified WA #1000 Kaisei stone belongs to the ultra-hard, high-density category, yet offers exceptionally strong cutting performance, significantly reducing the time required for the middle polishing stage in sword polishing.

🔹 Highly effective for severely damaged edges

Quickly removes deep scratches, chips, and structural irregularities.

🔹 Actual polishing fineness ≈ competitor #3000 stones

Leaves a refined, soft sheen far beyond a standard #1000.

🔹 Dense & uniform abrasive structure

Minimizes deep scratches and transitions smoothly to finer stones.

🔹 Ideal for Japanese swords & high-end kitchen knives

Perfect for mid-stage leveling and correction work.

Sword polishing focuses on:

・Hamon (刃文) definition

・Edge integrity

・Hada / Ji (地肌) refinement

・A smooth progression toward final finishing

This WA #1000 Meito Kaisei serves as the:

👉 Core mid-stage stone — “Repair → Entering fine polishing.”

A Kyoto-based whetstone kiln workshop producing:

・Industrial stones

・Stonework stones

・Kitchen knife stones

・Sword-polishing stones

Each whetstone is handmade, one by one by skilled artisans, with support for small-batch customization and grit adjustments.

As natural stones become rare and inconsistent, Arimoto collaborates closely with professional togishi and craftsmen to develop high-consistency synthetic stones that approximate natural stone behavior—highly regarded in the Kansai and Western Japan polishing circles.

Natural stones have become increasingly difficult to obtain and vary greatly in quality:

・Inconsistent cutting feel

・Unstable polishing results

・Irregular sizes and availability

Thus, sword polisher Masumi Association / Mr. Masaaki Matsunaga worked with Arimoto Seitosho to develop this series—designed specifically for sword polishing—to create a more predictable and smoother sharpening workflow.

Coarse → Medium → Fine

Used for:

・Correcting geometry

・Removing rust & chips

・Setting lines and shaping

👉 This WA #1000 belongs to the core mid-stage corrective stone category.

After geometry is perfected, finer stones highlight:

・Hamon brilliance

・Blade luster

・Texture depth

・The aesthetic and spiritual essence of the blade

📌 Note:

Authentic Japanese sword final polishing must use natural stones such as:

・Uchigumori

・Narutaki

・Other traditional shiage stones

This WA #1000 is the critical step before entering natural stone finishing.

・Use by sprinkling or spraying water (❌ Do not soak)

・Rinse with clean water after use; dry in shade

・Flatten periodically with a dressing stone or diamond plate

・Avoid sunlight, heat, and rapid drying

#ArimotoSeitosho #KyotoMade

#SwordPolishingStone #MeitoCertified #KaiseiStone

#WA1000 #MidPolishing #TogishiTools

#JapaneseSword #Whetstone #KitchenKnifeStone

#HeXinHang #和欣行