![]() 【現貨補貨】熱銷款再到貨|

【現貨補貨】熱銷款再到貨|

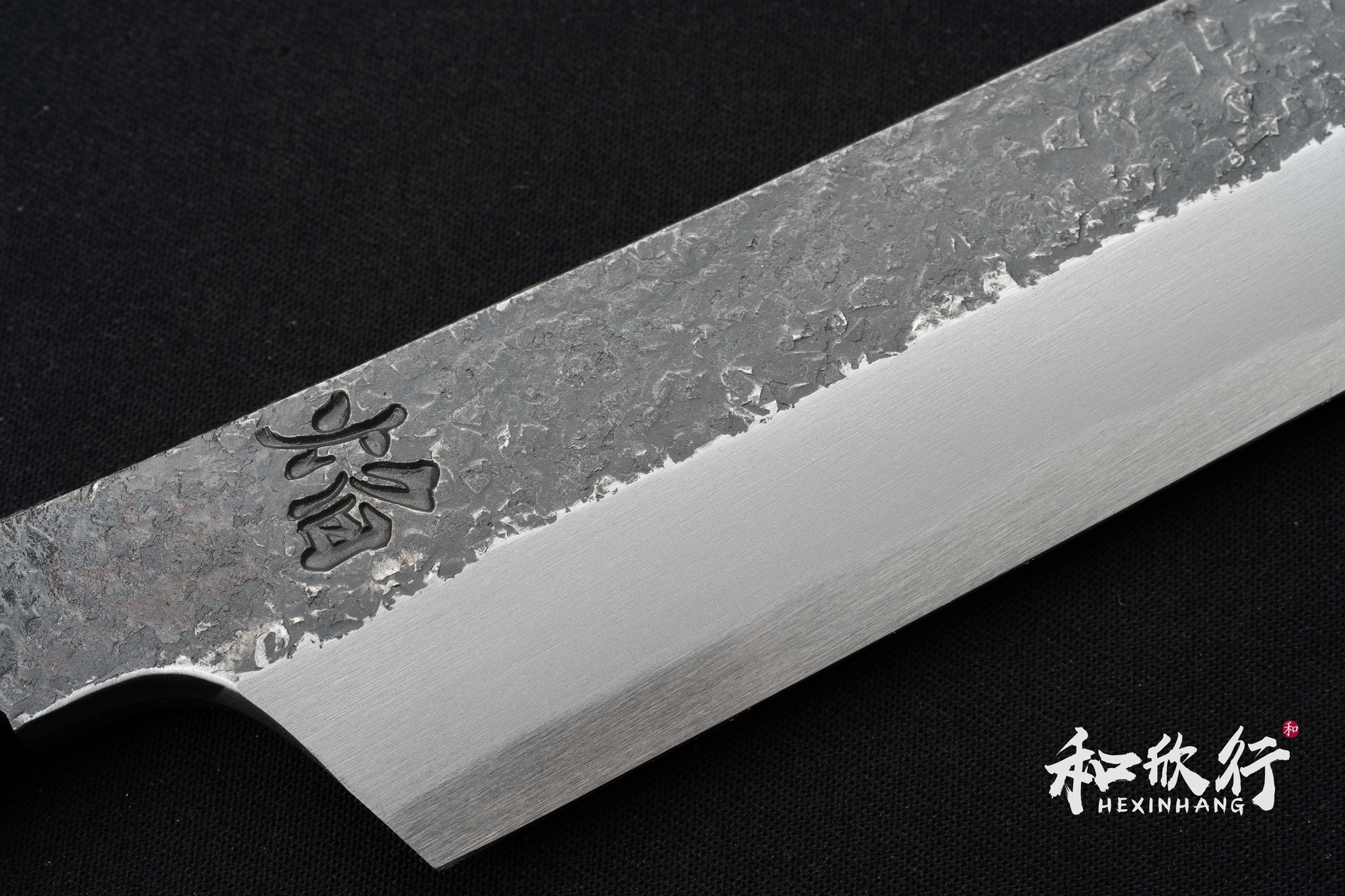

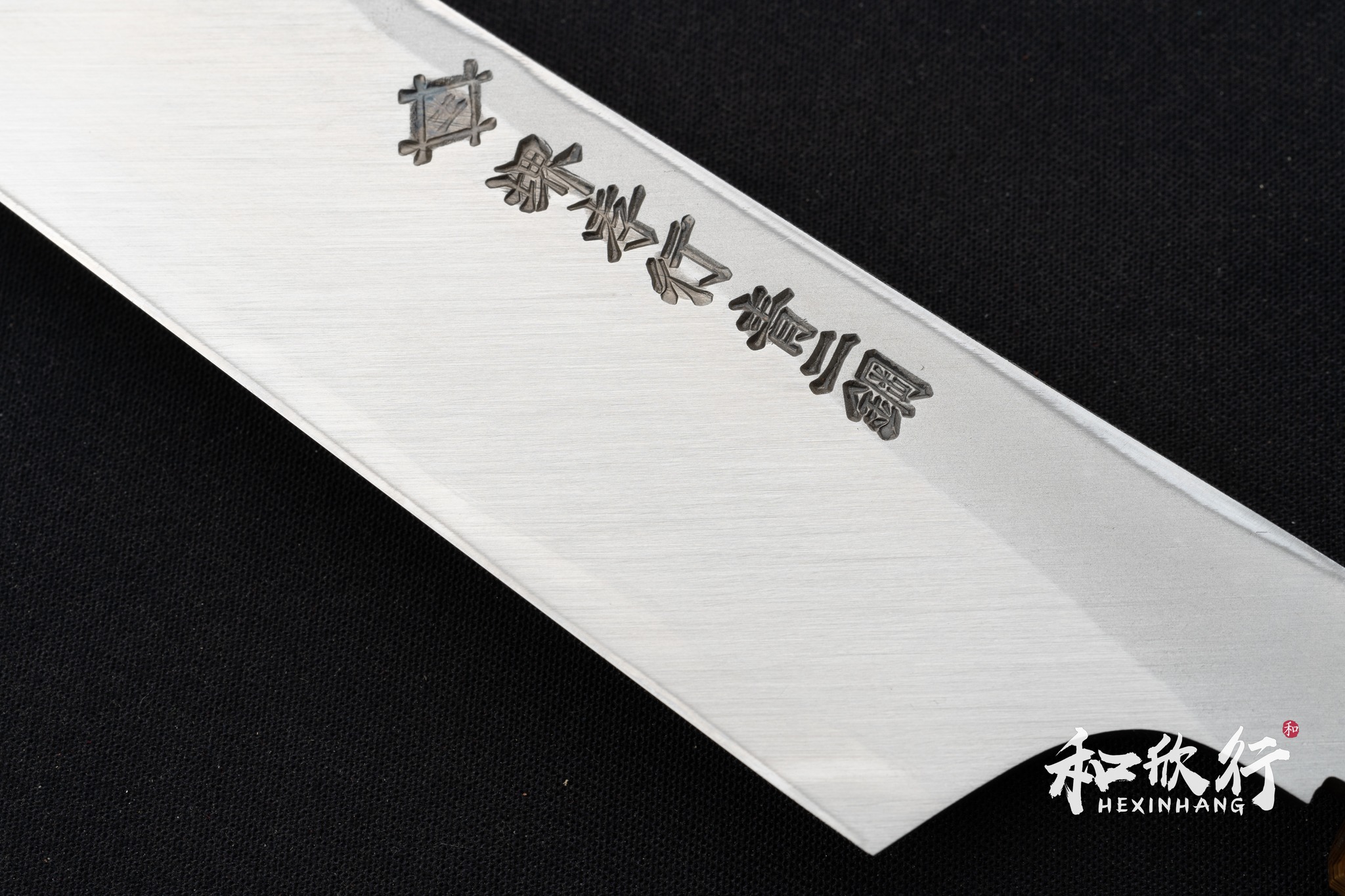

堺孝行「焰 紅蓮 玄武」先丸正夫 300mm ![]()

![]() 特殊曲背刀型 × 黑打槌目刀面 × 青二鋼極致鍛造

特殊曲背刀型 × 黑打槌目刀面 × 青二鋼極致鍛造

由知名刀匠「土井逸夫」先生手工打造

再附贈一包象徵火魂的「小松炭」,極具紀念價值

![]() 商品規格

商品規格

・鋼材:青二鋼(會生鏽,請妥善保養)

・鍛製:土井逸夫(三代青二鋼專業鍛匠)

・刃長:290mm(標示規格 300mm)

・刃寬:約 3.9cm

・刃厚:約 4.5mm

・柄長:約 140mm

・重量:約 258g

・柄材:燒櫟木

・鞘:可訂製(圖示為鐵刀木款)

![]() 不含鞘 NT$12,500(官網價)|Shopee 價:NT$13,500

不含鞘 NT$12,500(官網價)|Shopee 價:NT$13,500

![]() 含鐵刀木鞘:NT$15,000

含鐵刀木鞘:NT$15,000

![]() 每把附贈日本傳統「小松炭」一包

每把附贈日本傳統「小松炭」一包

![]() 關於刀的靈魂|從「松炭」開始說起

關於刀的靈魂|從「松炭」開始說起

在日本傳統鍛刀工藝中,火是萬物之始。

而「木炭」,特別是「松炭」,被視為製刀的靈魂之一:

![]() 炭火穩定、火力高且可控,適合精細的低溫鍛造

炭火穩定、火力高且可控,適合精細的低溫鍛造

![]() 松炭極適於青鋼的淬火與鍛煉

松炭極適於青鋼的淬火與鍛煉

![]() 然因產量稀少,現多以焦炭輔助,僅最頂級刀具仍堅持使用

然因產量稀少,現多以焦炭輔助,僅最頂級刀具仍堅持使用

松炭火焰溫度約落在850度,這正是青二鋼最理想的鍛造範圍。

如今仍堅持使用松炭的匠人,實屬極珍貴!

![]() 推薦觀看:日本刀炭火鍛造紀錄片

推薦觀看:日本刀炭火鍛造紀錄片

![]() 鋼材知識簡述|青二鋼(Aogami #2)

鋼材知識簡述|青二鋼(Aogami #2)

・鋒利 × 持久性極佳,是高階日料職人的首選

・相比青一鋼,青二更易研磨與保養

・硬度高於白二鋼,適合長時間大量切割生魚片

・唯一缺點:易生鏽,需定期保養

![]() 鋼材等級排行:青鋼 > 白鋼 > 黃鋼

鋼材等級排行:青鋼 > 白鋼 > 黃鋼

*名稱源自鋼材包裝用紙的顏色標記,非成分或色澤

![]() 刀匠介紹|土井逸夫(1948–)

刀匠介紹|土井逸夫(1948–)

出身於三代鍛匠世家,承襲「土井家青二鋼鍛造技法」

・父親:土井敬次郎

・祖父:土井一雄

・弟子生涯起自 24 歲,專精青二鋼鍛造近五十載

・製作堺孝行「特上」與高端青鋼系列作品

「切炭三年,對錘十年」,土井先生將一生獻給鐵火與鋼魂

![]() 從炭火到料理,是一段由職人到饕客的感動之旅

從炭火到料理,是一段由職人到饕客的感動之旅

一把好刀,是天時、地利、人和的結晶。

如同一道絕妙料理,來自對的人 × 對的食材 × 對的工具 × 對的味覺知音。

若你正是那位對的人,這把刀,正在等你。

![]() 私訊洽詢現貨或下單詳情,數量有限,售完即止!

私訊洽詢現貨或下單詳情,數量有限,售完即止!

![]() #堺孝行 #焰紅蓮 #土井逸夫 #松炭鍛造 #青二鋼 #日本鍛造刀 #黑打槌目 #職人之魂 #HeXinHang #和欣行

#堺孝行 #焰紅蓮 #土井逸夫 #松炭鍛造 #青二鋼 #日本鍛造刀 #黑打槌目 #職人之魂 #HeXinHang #和欣行

🔥【Now Restocked – Large Size Available】

Sakai Takayuki "Homura Guren Genbu" Sakimaru Yanagiba 300mm

⚔️ Signature curved-back profile × Kurouchi hammered finish × Master-forged Aogami #2 steel

Crafted by renowned blacksmith Itsuo Doi, with a bonus gift of traditional Komatsu charcoal, symbolizing the soul of fire.

—

🔧 Product Specifications

・Steel: Aogami #2 (carbon steel – prone to rust; proper care required)

・Blacksmith: Itsuo Doi – Master of Aogami steel forging

・Blade length: Approx. 290mm (listed as 300mm)

・Blade width: Approx. 3.9cm

・Blade thickness: Approx. 4.5mm

・Handle length: Approx. 140mm

・Weight: Approx. 258g

・Handle: Yakisugi (charred oak wood)

・Saya (sheath): Custom order available (sample shown in Tietam wood)

💰 Price (knife only): NT$12,500 (official site) | Shopee: NT$13,500

💰 Price with Tietam wood saya: NT$15,000

📦 Includes a pack of traditional Japanese Komatsu charcoal

—

🌲 The Soul of the Blade: Fire and Charcoal

In traditional Japanese blade smithing, fire is the essence of creation.

Pine charcoal, especially Komatsu charcoal, is considered the soul of the blade:

・Stable flame with high, controllable heat – perfect for fine forging

・Ideal for quenching and tempering Aogami steel

・Due to rarity, now replaced by coke in most forges – only top-tier blades still use true pine charcoal

Pine charcoal burns around 850°C – the perfect heat zone for Aogami #2 steel.

Blacksmiths who still insist on Komatsu charcoal are exceedingly rare today.

🎥 Recommended documentary: Traditional Japanese Forge Using Charcoal

👉 Watch here

—

🔬 Steel Overview: Aogami #2 (Blue Paper Steel)

・Excellent sharpness and edge retention – top choice for professional chefs

・Easier to sharpen and maintain compared to Aogami #1

・Harder than White #2 steel, ideal for prolonged sashimi slicing

・Note: Carbon steel is prone to rust – regular maintenance needed

Steel Rank by Performance: Aogami > Shirogami > Kigami

(Names refer to the color of paper wrappers used in classification, not the steel’s color.)

—

👨🏭 About the Blacksmith: Itsuo Doi (b. 1948)

A third-generation blacksmith continuing the Doi family’s Aogami forging legacy.

・Father: Keijiro Doi

・Grandfather: Kazuo Doi

・Started apprenticeship at age 24

・Nearly 50 years of expertise in Aogami steel

・Maker of Sakai Takayuki’s “Tokujou” and premium Blue Steel lines

"Three years to master charcoal, ten to master the hammer."

Itsuo Doi has devoted his life to the flames and the soul of steel.

—

🍽️ From Forge to Table – A Journey of Craftsmanship

A great knife is a harmony of time, place, and people – just like a great dish.

If you’re the right chef, collector, or artisan appreciator...

This knife is waiting for you.

📩 Message us to inquire or place your order – limited quantity available!

🔖 #SakaiTakayuki #HomuraGuren #ItsuoDoi #KomatsuCharcoal #AogamiSteel #JapaneseKnives #KurouchiFinish #ForgedWithSoul #HeXinHang